-

-

-

News

- Analysis of the Misunderstanding of MBBR and the Application of MBBR in Guangdong

- Add time: 2019-10-17 Hits:693

-

Introduction:

On September 26, 2019, Qingdao Spring Water Treatment Co. , Ltd. was invited to the 2019 Water Safety and Water Environment Comprehensive Rehabilitation in Guangzhou ,which focused on the Guangdong-Hong Kong-Macao Dawan District Water Environment Construction Summit Forum and "China Water Supply and Drainage" Sixteenth annual meeting.

MBBR has been promoted in China for more than 10 years, and a large number of actual engineering cases have emerged, but in fact the industry is unfamiliar with MBBR. It is known in the industry that the MBBR process enhances the treatment effect by adding a suspension carrier to the reactor, but it is easy to underestimate its hydraulic design, while ignoring the difference between biofilm and activated sludge.

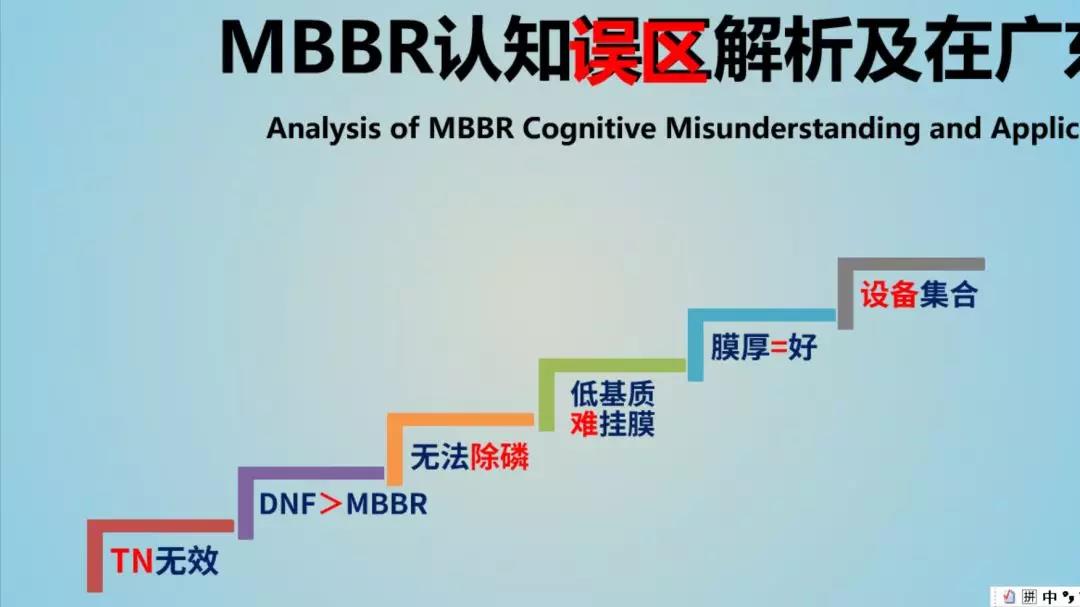

The main misunderstandings of MBBR include the enhancement effect of suspension carrier on nitrogen and phosphorus removal, the biofilm properties and membranes, and the materialization of MBBR technology.

1. Misunderstanding 1

Adding suspension carrier can enhance ammonia nitrogen removal , but cannot enhance TN removal. In fact, the first half of sentence is correct. The most intuitive effect of MBBR is to increase biomass and enhance bio-enrichment. The biofilm sludge retention time is much higher than that of the activated sludge, and the suspension carrier is retained in the specific active area, which is beneficial to enrich and cultivate bacteria. By tracking existing projects, we found that the abundance of nitrifying bacteria on biofilms was 10 times more than that of activated sludge, and the species of nitrifying bacteria were optimized. The qualitative and quantitative changes of nitrifying bacteria greatly enhance the system nitrification effect.

On the basis that the suspension carrier can enhance the nitrification, nitrification is no longer a limiting factor of the system function. We can preferentially satisfy the anoxic denitrification by borrowing the aerobic pool capacity. The lack of nitrification caused by insufficient aerobic capacity can finally be supplemented by adding a suspension carrier through the aerobic zone. Adding suspension carrier directly to the anoxic zone will increase several times agitation energy consumption and the improvement of the system's removal load resistancect is limited, which is not a priority.

The stratified distribution of biofilms creates conditions for the emergence of simultaneous nitrification and denitrification (SND). The proportion of stable denitrification on the suspension carrier also provided microbiological evidence for simultaneous nitrification and denitrification.

Therefore, based on the enrichment of nitrifying bacteria by suspension-supporting, the removal of TN can be enhanced by the optimal regulation of pool capacity and simultaneous nitrification and denitrification (SND).

2. Misunderstanding 2

It is believed that TN cannot reach the quasi-IV water standard under the requirement of TN<10mg/L in the biochemical section, and the denitrification filter must be added. Taking our experience in upgrading and renovating the 160, 000 t/d wastewater treatment plant in Ningbo Xinzhou as an example, in order to ensure TN compliance, Bardenpho-MBBR was designed in the biochemical section. TN removal was ensured through the five-stage post-hypoxia section. At the same time, deep processing increases the deep bed denitrification filter to further increase reliability. The practice of the Xinzhou shows that Bardenpho-MBBR can fully guarantee the stability of effluent TN, and the effluent TN of biochemical pool can be stabilized less than 10mg/L. In the case of no carbon source, 6-8mg/L of TN is removed before the transformation. In the case of a large impact, the carbon source stabilization treatment can be directly applied in the post-anoxic zone, and the C/N ratio of the anoxic zone is 3-3. 5. The modified denitrification filter has been operated as an ordinary filter and has not been optimized for investment. Bardenpho-MBBR can completely replace the TN removal function of the denitrification filter, and the advanced processing unit selects the general filtering technology to ensure the compliance of the overall indicators. Since the influent DO is relatively high, the C/N ratio is as high as 7-9, and the removal of 5 mg/L TN is taken as an example. The cost of the carbon source per ton of water is 0. 22 yuan. Selecting the MBBR process can save the cost of this part of the carbon source, saving 13 million yuan a year, and recovering all the investment of MBBR in 4 years. Therefore, MBBR can stably reach the quasi-IV water standard in both theoretical and practical denitrification, which is one of the feasible ways to upgrade the biochemical pool.

3. Misunderstanding 3

It is believed that phosphorus removal is only related to sludge removal, and MBBR loading cannot enhance biological phosphorus removal. In response to this problem, a case of MBBR enhanced biological phosphorus removal was introduced, Qingdao Tuandao Sewage Treatment Plant. In 2010, the MBBR transformation was adopted, and the effluent after the transformation was stable to the first-class A standard. The influent TP of the bio-pool of the Tuandao Plant is about 9mg/L, the TP of the biochemical section can be stabilized less than 1mg/L, and the TP removal rate of the biological section is as high as 88%, which greatly saves the cost of deep processing of pharmaceuticals. The strengthening of biological phosphorus removal in Tuandao is inseparable from the suspension carriers. The activated sludge method has the contradiction of sludge age, and it is difficult to balance the effects of nitrogen and phosphorus removal. The dosing of the suspension carrier makes the system a double sludge retention time structure. The sludge retention time of the fixed suspension carrier biofilm is long and can meet the growth demand of nitrifying bacteria. Therefore, the suspended sludge age of the activated sludge can be appropriately shortened, and the biological phosphorus removal effect can be enhanced.

4. Misunderstanding 4

MBBR is difficult to grow biofilm under low matrix conditions, and many owners, especially those in the southern region, are worried that the influent concentration is low and the biofilm does not grow. According to our actual engineering experience, the sewage plant will hang membranes for 1-2 weeks in summer and 3-6 weeks in winter. Taking the Guangzhou DaTanSha pilot test as an example, biofilm enrichment can be clearly observed in 7 days, and the biofilm is relatively mature in 60 days. Another lower matrix case is the feedwater pretreatment project ,which has just been done this year. The influent ammonia nitrogen is only 2mg/L, but the suspension carrier biofilm grows well in the pool. The second group has biofilm adhesion within 10 days after adding the suspension carrier. In fact, the matrix is not the most critical factor affecting the suspension carrier film, the most important is the control of operating conditions, especially fluidization. The shear force provided by fluidization stimulates the secretion of extracellular polymeric EPS, which enhances the growth of biofilm on the suspension carrier. Hydraulic shearing is an important external condition for microbial enrichment, screening and evolution, and also a necessary condition for dynamic renewal of biofilm. By optimizing the control, it is possible to avoid the impact of low water concentration on the film. The lower the water concentration is, the higher experience of control is needed, so it is necessary to ensure hydraulic shear to achieve biofilm normal growth.

5. Misunderstanding 5

The thicker the MBBR biofilm, the better. A basic logic is that the thicker the biofilm is , the more biomass it has, and the more effective the treatment would be . However, this view ignores the fact that biofilm method is different from activated sludge, and mass transfer is the common bottleneck of biofilm process. In order to enhance mass transfer, MBBR optimizes the traditional fixed bed as a moving bed. If there is a problem with mass transfer, a amount of biomass will have no effect. On the one hand, the internal flow passage area of the suspended carrier is limited, and increasing the thickness of the biofilm will lead to narrowing of the flow path, increasing the surface tension and reducing the actual effective specific surface area. System mass transfer is blocked。On the other hand, the DO penetration ability is limited. If the biofilm is thicker and the anaerobic layer is easily formed, the anaerobic fermentation will cause the biofilm to fall off at the same time and affect the treatment effect. Therefore, a good biofilm is a dense film. The MBBR process should ensure good biomass transfer and oxygen transfer instead of simply increasing the biofilm thickness.

6. Misunderstanding 6

Some equate MBBR with a simple collection of devices, only to see that the device ignores the design,even materializing MBBR technology. Companies with this perception are very prone to failures. Only by unifying equipment, design and services can we achieve the success of MBBR. The most important thing to break through MBBR hydraulics is to weigh the relationship between suspended carriers, interception and fluidization. The specific gravity of the carrier determines the difficulty of fluidization. The size of the suspension carrier determines the size of the intercepting screen, and the fluidization provides clean power for the screen.

The choice of suspension carrier requires a combination of its appearance, materials and parameters. In appearance, laboratory research results show that both spherical and sponge fillers have achieved good results。However, in engineering, spherical fillers are difficult to fluidize hydraulically, and the texture is brittle; sponge fillers are severely worn and internal mass transfer is difficult. At present, flat cylindrical packing is widely used at home and abroad. In terms of material, high-density polyethylene HDPE meets the requirements of suspension carrier in terms of density, aging resistance and thermoplastic precision. In order to ensure the overall life of the MBBR system, the industry standard prohibits the use of recycled materials to produce suspended carriers to prevent a large amount of inorganic substances such as carbon black, which affects the service life. The Spring suspension carrier is made of HDPE pure material, and the service life of the suspension carrier is more than 15 years. Wuxi Lucun Wastewater Treatment Plant has been operating stably for 11 years and the filling condition is good. The most critical parameter of the suspension carrier is the effective specific surface area, what is the area that can be grown by microorganisms and achieve good mass transfer and oxygen transmission. There are many fillers on the market, and the effective specific surface area cannot be judged by the naked eye. Therefore, the industry standard issued by the Ministry of Housing and Urban-Rural Development in 2014 stipulated a variety of commonly used suspended carriers in the market, and the corresponding effective surface area was determined by expert argumentation. The newly revised outdoor drainage design standard specifies that MBBR is designed for surface load. Once the effective specific surface area is falsified, it will inevitably lead to insufficient processing capacity, and eventually the effluent water quality will not meet the standard.

We recommend a uniform suspension carrier model based on industry standards when selecting carriers.

In terms of fluidization, in addition to promoting mass transfer and oxygen transmission, it also provides power for screen cleaning and anti-blocking. In actual engineering, full fluidization of the suspension carrier can be achieved by both the circular flow type and the micro hybrid type.

Service is also an indispensable part. Through the tracking and return visits of existing cases, we further explored the technological advantages of MBBR, and optimized the operation and enhanced the processing effect to achieve the gain of MBBR performance. Therefore, the MBBR process is not a simple equipment combination, but also includes a complete service system such as hydraulic design, fill rate design, and optimized operation. MBBR is a complete process package implemented by professional manufacturers.

The above is our understanding of the common misunderstanding of MBBR. MBBR can strengthen biological nitrogen and phosphorus removal. Under the condition of S-IV water standard, the biochemical section can guarantee the compliance of ammonia nitrogen and TN. The suspension carrier film is not restricted by water concentration, and the biofilm should be guaranteed good mass transfer and oxygen transmission during operation. MBBR technology should be viewed as process package and systems.

In the process of continuous exploration and research on MBBR, Spring optimizes the process according to the characteristics of water quality in Guangdong. At present, the number of regional performance has reached 14 and the total treatment volume is 142. 6wt/d. Next, we report the actual operation of MBBR in Guangdong through several typical cases of MBBR in Guangdong.

The first case is the Guangzhou Datansha Wastewater Treatment Plant with a capacity of 550, 000 t/d. Its effluent needs to be labeled to S- V. The Datansha Wastewater Treatment Plant mainly faces the following problems, First of all, there is a shortage of influent carbon sources commonly encountered in Guangdong, affecting the efficiency of nitrogen removal. In addition, the influent water has strong impact, and it is necessary to co-process the landfill leachate, which has high requirements on the system's impact resistance. Finally, there is no expansion of land, only the original pool retrofitting. The retrofitting adopts the Lucun process method, cutting the aerobic pool capacity to prolong the anoxic pool capacity, and setting the MBBR region to strengthen the nitrification stability in the aerobic middle section. In view of the large amount of water in the Datansha WWTP, the problem is universal and representative. To ensure the feasibility of the MBBR program, the owner and the Guangzhou Municipal Government organized a pilot test. In the verification phase of the scheme, the carbon source was not added in the whole process, and the TN removal amount increased 4. 5mg/L compared with the sewage plant in the same period. Under the same reflux ratio, the treatment effect is still better than that of the existing water plant. At the same time, the simultaneous nitrification and denitrification phenomenon is also found along the path analysis, which further strenghthen the TN removal. Water impact is also a common problem faced by southern sewage plants. The pilot test simulates 1. 3/1. 4 times water volume impact conditions, the short-term fluctuation of ammonia nitrogen is rapid and stable, TN remains stable, and the assessment indicators reach the discharge standards. When the landfill leachate is treated in coordination, the nitrogen load of the system is obviously improved, which further aggravates the disadvantages of low C/N. Although leachate is biochemically inhibited, MBBR still exhibits a stable and efficient treatment effect. In terms of the removal of TP, in view of the characteristics of MBBR double sludge retention time, the effective sludge retention time is appropriately reduced to ensure the good effect of biological phosphorus removal. Under the premise of not adding flocculant, the effluent TP is generally lower than 0. 4mg/L.

The second case is Shenzhen Beikong Waterworks Hengling Wastewater Treatment Plant. The sewage treatment capacity is 200, 000 t/d, and the effluent is subject to S-IV standard, facing the challenges of water intrusion, strict assessment standards, and relatively low temperature in winter. The transformation idea is to change the aerobic first corridor to the anoxic zone, and add the suspension carrier in the aerobic zone to set up the MBBR zone, using a micro-dynamic mixing pool type. After the MBBR transformation, there is no need to add any carbon source, and the effluent TN is stable at 7-8. The actual removal rate of TN has exceeded the theoretical value, and there is obvious simultaneous nitrification and denitrification. In terms of phosphorus removal, due to the separation of MBBR sludge retention time and enhanced biological phosphorus removal, the process plus PAC amount is only one tenth of the second phase biofilter. In addition, the impact load capacity of MBBR is significantly better than that of the second stage project when the water inflow is fluctuating, and the effluent is more stable.

The third case is Foshan Gaoming Sewage Treatment Plant. The design scale of the sewage plant is 100, 000 t/d, and the biochemical section adopts the A2/O micro-exposure oxidation ditch process commonly used in Guangdong. The oxidation ditch modification is different from the A2O corridor, and it is necessary to maintain the overall fully mixed reactor flow regime. When the Gaoming plant is rebuilt, the oxygen-deficient partition wall will be moved backwards, and the large pool capacity will be inserted, and a small circulating MBBR pool will be nested in the large oxidation ditch. After the transformation, the stability is up to standard, and the average value of total nitrogen effluent can reach 8. 3mg/L. There is no need to add carbon source throughout the year.

The fourth case is Huizhou Shiwan Wastewater Treatment Plant. Although the treatment capacity of the sewage treatment plant is only 30, 000 t/d, the two processes of A2/O and CASS are adopted in one or two phases. The CASS transformation is different from the continuous flow process. Factors such as time distribution, fluidization of the suspension carrier, and decanter need to be considered, which increases the difficulty of reconstruction. CASS adopts MBBR to transform unmoved civil works, and the construction period is short. The intercepting screen is installed at the end of the main reaction zone to protect the decanter. The filling fluidization is good without accumulation, and the effluent is stable. The application of MBBR technology in Guangdong covers mainstream technology and special water quality. The MBBR treatment effect is stable, and the company has accumulated rich experience in engineering design and debugging. At the same time, the company continues to advance in technology and continuously develops the potential and advantages of MBBR in the process of working with the owners. Professionalism, dedication and specialization are the business philosophy of Spring. For more than 10 years, the company only does one thing, it is MBBR, which guarantees the reasonable design and engineering implementation quality of MBBR technology package. It is our principle and creed to achieve stable water standards at all costs. Spring has the confidence and ability to work with the majority of water people to improve the regional water environment, to fulfill the responsibility of human beings for environmentally sustainable development, and to create harmony between human-being and nature. Thank you all!

-

- LINKS